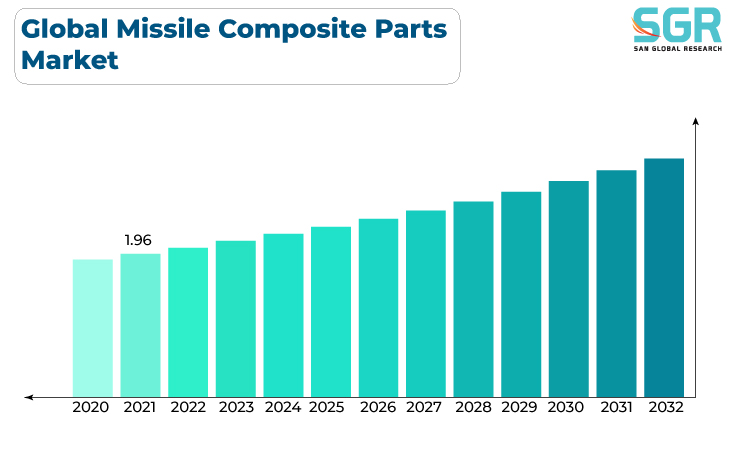

Global Missile Composite Parts market is estimated to be worth USD 1.23 Billion in 2022 and is projected to grow at a CAGR of 9.6% between 2021 to 2032. The study has considered the base year as 2022, which estimates the market size of market and the forecast period is 2021 to 2032. The report analyzes and forecasts the market size, in terms of value (USD Million), for the market. The report segments the market and forecasts it by type, by application, and region/country.

The global missile composite parts market is a niche segment within the broader composite parts market, focusing specifically on the production and use of composite materials in missile systems. Composite materials offer several advantages in the construction of missile components, including reduced weight, increased strength, and improved resistance to extreme conditions. The global missile composite parts market is a relatively small but essential segment of the broader defense industry. It includes various composite components used in the construction of missiles, such as airframes, warhead casings, fins, and control surfaces. Composite parts are used in various types of missiles, including air-to-air missiles, surface-to-air missiles, anti-ship missiles, cruise missiles, and ballistic missiles. The market is influenced by ongoing advancements in composite manufacturing technologies, such as automated fiber placement and resin transfer molding.

Region Wise Comparison:

North America, particularly the United States, plays a leading role in the global missile composite parts market. The U.S. is home to major defense contractors, aerospace manufacturers, and composite material companies involved in the development and production of missile components.

Europe has a significant presence in the global missile composite parts market, with countries like the United Kingdom, France, Germany, and Italy participating in the design and manufacturing of composite parts for missile systems.

The Asia-Pacific region is a rapidly growing market for missile composite parts, driven by the modernization of missile systems in countries like China, India, South Korea, and Japan.

The Middle East and North Africa regions have increased their involvement in the production and use of composite parts for missile systems as part of defense and security strategies.

Latin America has a smaller share of the global missile composite parts market compared to other regions, with some countries participating in the production of components for missile systems.

Africa's presence in the global missile composite parts market is relatively limited. However, some countries have started to develop and utilize composite materials in missile construction.

Segmentation:

The Missile Composite Parts market is segmented by type, by application, and region/country.

Based on the Type

- Shells & Covers

- Guidance & Control Components

- Structural Supports & Brackets

- Others

Based on Application

- Military Defense

- Tactical Strike

- Counter Terrorism

- Others

On the basis of region

- North America

- Europe

- Asia Pacific

- South America and

- Middle East and Africa

In 2022, North America is anticipated to dominate the Missile Composite Parts market with market revenue of XX USD Million with a registered CAGR of XX%.

Key Players:

The key market players operating in the Missile Composite Parts market include

- Rolls Royce

- Consolidated Precision Products

- Anhui Shenjian New Materials Co., Ltd.

- Shanghai Hugong Electric Group Co., Ltd.

- Lockheed Martin

- Almaz-Antey

- Jiang Su Xinyang New Materials Co.,ltd.

- Anhui Jialiqi Advanced Composites Technology Co., Ltd.

- Xi'an Bright Laser Technologies Co.,ltd.

- GUIZHOUAEROSPACETIANMAELECTROMECHANICALS&T Co., Ltd.

Drivers:

Growing defense programs across global

The global missile composite parts market is influenced by several factors that drive the demand for composite materials in the production of missile components. These drivers can vary by region and are subject to changes over time. The need for lightweight missile systems with enhanced performance drives the use of composite materials. Composite parts offer high strength-to-weight ratios, improving missile range and maneuverability. Military modernization programs and the upgrading of missile systems are key drivers of the market. Countries seek to enhance their missile capabilities with advanced materials. Ongoing advancements in composite material technologies, including the development of new resin systems, fibers, and manufacturing processes, contribute to the growth of the market.

Opportunity:

Technology Advancements

The global missile composite parts market presents several opportunities for businesses, defense contractors, and technology providers. These opportunities arise from the growing demand for advanced composite materials in the production of missile components, as nations seek to enhance their missile systems and capabilities. Opportunities exist for companies that can develop and supply advanced composite materials tailored to the unique requirements of missile systems, including materials with improved strength, durability, and resistance to extreme conditions. The development of innovative manufacturing techniques for composite parts, such as automated fiber placement and resin transfer molding, can provide competitive advantages and create market opportunities. Offering custom-designed composite solutions tailored to the specific requirements of missile programs and applications provide market opportunities for businesses.

Description

Description

Gera Imperium Rise,

Gera Imperium Rise,  +91 9209275355

+91 9209275355